Welcome to the PAC SNI 35 wiring guide․ This manual provides comprehensive instructions for installing and configuring PAC SNI 35 systems, ensuring safety, efficiency, and compliance with industry standards for professionals․

Understanding the PAC SNI 35 Standard

The PAC SNI 35 standard outlines specifications for electrical wiring in industrial and commercial settings, ensuring reliability, safety, and efficiency in electrical systems․ It serves as a foundational guide for technicians and engineers․

2․1․ What is PAC SNI 35?

PAC SNI 35 is a standardized specification for electrical wiring systems, primarily used in industrial and commercial applications․ It provides detailed guidelines for the installation, testing, and maintenance of electrical infrastructure to ensure safety and efficiency․ The standard covers various aspects, including conductor sizing, insulation requirements, and connection methods, to meet the demands of modern electrical systems․ Compliance with PAC SNI 35 is essential for ensuring system reliability and adherence to safety protocols․ It is widely recognized and adopted by professionals in the field, serving as a benchmark for best practices in electrical wiring․ By following PAC SNI 35, technicians and engineers can ensure that electrical installations are durable, efficient, and compliant with industry regulations․

2․2․ Scope and Application

The PAC SNI 35 standard is designed to regulate electrical wiring practices in various settings, ensuring consistency and safety․ Its scope encompasses industrial, commercial, and residential environments, providing guidelines for both new installations and upgrades․ The standard applies to power distribution systems, lighting, control circuits, and communication networks․ It specifies requirements for conductor types, insulation, and connection methods to ensure reliability and durability․ Additionally, PAC SNI 35 covers safety measures for grounding, bonding, and surge protection to prevent hazards․ The standard is particularly relevant for professionals, including electricians, engineers, and contractors, who need to comply with national and international electrical codes․ By adhering to PAC SNI 35, installations can meet regulatory requirements and industry best practices, ensuring optimal performance and safety․ This standard is widely applicable, making it a critical reference for modern electrical wiring projects․

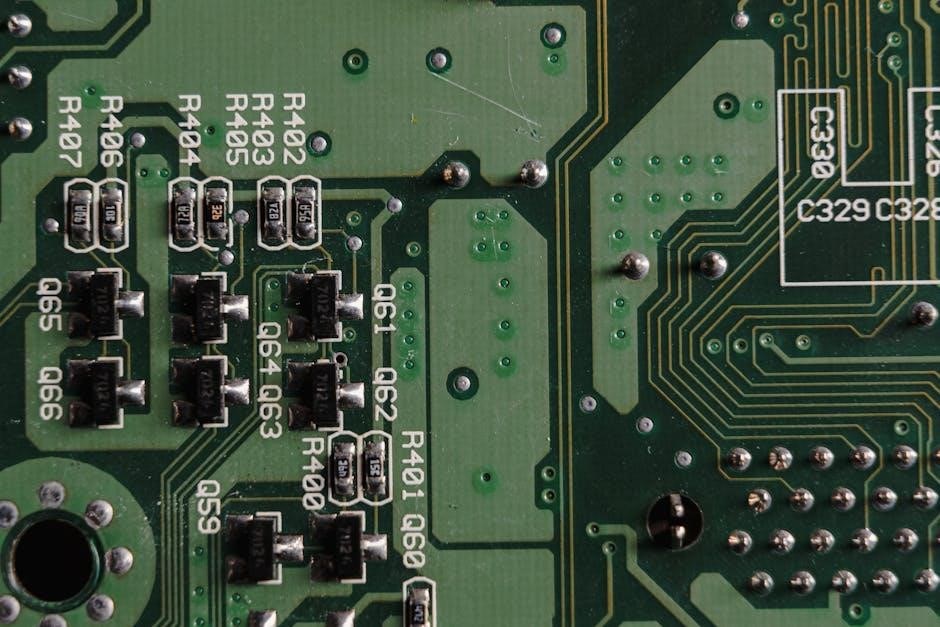

Key Components of PAC SNI 35 Wiring

The PAC SNI 35 wiring system relies on essential components like high-quality cables, circuit breakers, connectors, and control panels․ Safety elements such as surge protectors and grounding systems are also critical for reliable operation․

3․1․ Essential Materials and Tools

To begin PAC SNI 35 wiring, gather essential materials such as high-quality copper wires, terminals, and connectors․ Ensure you have insulated cables, circuit breakers, and grounding wires for safety․ Tools like wire strippers, crimpers, screwdrivers, and multimeters are crucial․ Additionally, safety gear such as gloves and goggles should always be on hand․ Using the right materials and tools ensures compliance with standards and prevents potential hazards․ Proper organization of these items will streamline the wiring process and minimize errors․ Always verify the quality and compatibility of components before starting work․ This preparation is fundamental for a safe and efficient installation․

3․2․ Safety Precautions

Safety is paramount when working with PAC SNI 35 wiring․ Always disconnect power sources before starting work and verify de-energization using a multimeter․ Wear personal protective equipment, including insulated gloves and safety goggles, to prevent electrical shocks and injuries․ Ensure the workspace is well-ventilated and free from flammable materials․ Follow proper lockout/tagout procedures to prevent accidental system activation․ Never overload circuits, and keep loose clothing and long hair tied back․ Be cautious of live wires and avoid working in wet conditions․ Regularly inspect tools and equipment for damage․ In case of an emergency, have a first aid kit nearby and know the proper procedures․ Adhering to these precautions minimizes risks and ensures a safe working environment․ Remember, electrical systems can be dangerous if not handled correctly, so vigilance is key throughout the process․

Step-by-Step Wiring Process

This section outlines the PAC SNI 35 wiring process, from preparation to final testing․ Follow each step carefully to ensure safety, efficiency, and compliance with industry standards for reliable system operation․

4․1․ Pre-Wiring Preparation

Before starting the wiring process, ensure all materials and tools are readily available․ Review the circuit diagrams and system requirements thoroughly․ Verify that all components, such as wires, connectors, and control units, are compatible with PAC SNI 35 standards․ Conduct a safety inspection of the workspace, ensuring it is clear of hazards․ Shut off power supplies to avoid accidental energization․ Familiarize yourself with the wiring sequence to maintain organization․ Double-check the documentation for any specific instructions or precautions․ Organize the workspace to streamline the process, and ensure all safety equipment, such as gloves and goggles, is accessible․ Proper preparation is key to a smooth and efficient wiring process, minimizing errors and ensuring compliance with safety protocols․

4․2․ Connecting the Power Supply

Connecting the power supply is a critical step in the PAC SNI 35 wiring process․ Begin by ensuring the power supply unit is compatible with the system’s voltage and current requirements․ Locate the power supply in a well-ventilated area to prevent overheating․ Connect the positive and negative terminals to the appropriate points on the control panel, referencing the wiring diagram for accuracy․ Use high-quality, insulated wires of the correct gauge to ensure safe and efficient power transmission․ Secure all connections tightly to avoid loose wires, which can cause malfunctions․ Install surge protectors or voltage stabilizers if required by the system specifications․ Double-check the polarity to prevent damage to components․ Finally, test the power supply by turning it on and verifying the output voltage matches the system’s requirements before proceeding with further connections․

4․3․ Wiring Input and Output Devices

Wiring input and output devices is a fundamental step in the PAC SNI 35 setup․ Begin by identifying the input devices, such as sensors and switches, and output devices like actuators and indicators․ Refer to the wiring diagram to determine the correct connections․ Use appropriately sized wires to ensure signal integrity and power transmission․ Connect input devices to the control module’s input terminals, ensuring proper polarity and wiring configuration․ For output devices, link them to the corresponding output terminals, following the system’s logic and control requirements․ Use twisted or shielded cables for noise-sensitive applications․ Secure all connections with crimped or soldered joints and label them for clarity․ Test each connection to verify functionality and isolate any issues before proceeding․ Properly routing and organizing wires will enhance system reliability and simplify future maintenance․ Always cross-verify connections with the system’s documentation to avoid mismatches․

4․4․ Programming the Control System

Programming the PAC SNI 35 control system is a critical step to ensure optimal performance․ Begin by preparing the system, including installing necessary software and drivers․ Use the provided configuration tools to set up input/output mappings, logic sequences, and operational parameters․ Upload the program to the control module, ensuring compatibility with the wiring setup․ Test the system thoroughly to validate functionality, checking each input and output for proper response․ Address any discrepancies by reviewing the wiring connections and adjusting the program as needed․ Document the final configuration for future reference and perform regular backups․ Always follow the manufacturer’s guidelines for programming and updates to maintain system integrity and compliance with standards․

4․5․ Final Connections and Testing

After completing the wiring, proceed to the final connections and testing phase․ Ensure all terminals are securely tightened and double-check the connections for accuracy․ Power up the system gradually, starting with the control module and progressing to peripheral devices․ Use a multimeter to verify voltage levels at critical points․ Test each input and output device to confirm proper functionality, simulating real-world scenarios to identify potential issues․ Pay special attention to safety mechanisms and fail-safes, ensuring they operate as intended․ Document any irregularities and address them promptly․ Once all components are verified, perform a full system test under load to confirm reliability․ Finally, review the entire setup to ensure compliance with PAC SNI 35 standards and prepare a detailed test report for future reference․ This step ensures the system is safe, efficient, and ready for operational use․

Compliance and Certification

Compliance with PAC SNI 35 ensures that wiring systems meet safety and efficiency standards, while certification validates adherence to these guidelines, guaranteeing reliability and industry acceptance․

5․1․ Importance of Compliance

Compliance with PAC SNI 35 wiring instructions is crucial for ensuring safety, efficiency, and reliability in electrical installations․ Adhering to these standards minimizes risks of electrical hazards, such as short circuits or fires, protecting people and property․ Compliance also guarantees that the wiring system meets industry performance benchmarks, ensuring optimal functionality and longevity․ Additionally, conforming to PAC SNI 35 requirements facilitates legal and regulatory acceptance, avoiding potential penalties or system rejection․ Proper compliance further enhances system maintainability and scalability, making future upgrades or modifications smoother․ By following these guidelines, professionals can deliver high-quality installations that align with both safety and operational expectations․ Ultimately, compliance is not just a regulatory necessity but a cornerstone of responsible and professional electrical work․

5․2․ Certification Process

The certification process for PAC SNI 35 wiring ensures installations meet rigorous safety and performance standards․ It begins with a thorough inspection of the wiring system by certified professionals to verify compliance with PAC SNI 35 requirements․ This includes checking materials, connections, and overall system design․ Once the inspection is passed, the system undergoes a series of tests to validate its functionality and safety under operational conditions․ Documentation, including test results and inspection reports, is then submitted to the relevant authorities for review․ If approved, a certification is issued, confirming the system’s adherence to the standard․ This certification not only ensures legal compliance but also enhances the system’s reliability and market acceptance․ Regular recertification may be required to maintain compliance, especially after system modifications or upgrades․ The certification process is a critical step in upholding the integrity and safety of electrical installations․

Common Mistakes to Avoid

- Incorrect wire sizing leading to overheating or voltage drop․

- Poor or loose connections causing electrical failures․

- Neglecting safety protocols, risking shocks or fires․

- Ignoring load calculations, resulting in system overload․

- Using non-compliant materials that compromise performance․

6․1․ Typical Errors in Wiring

Common wiring errors in PAC SNI 35 installations include incorrect wire gauges, improper connections, and misidentification of terminals․ These mistakes can lead to system malfunctions, safety hazards, or non-compliance with standards․ One frequent issue is using wires that do not meet the required specifications, causing voltage drops or overheating․ Another error is connecting wires to the wrong terminals, which can result in short circuits or equipment damage․ Additionally, neglecting to follow the recommended wiring sequence can disrupt the entire system’s performance․ Improper insulation or insufficient spacing between wires may also lead to electrical interference or fire risks․ Addressing these errors requires careful planning, adherence to diagrams, and double-checking connections before powering up the system․ Regular inspections and troubleshooting are essential to ensure reliability and safety in PAC SNI 35 wiring projects․

6․2․ Troubleshooting Techniques

Troubleshooting PAC SNI 35 wiring issues requires a systematic approach to identify and resolve faults efficiently․ Start by reviewing the wiring diagram to verify connections and ensure all components are correctly linked․ Use a multimeter to check voltage levels, continuity, and resistance, which can help pinpoint breaks or short circuits․ Inspect wires for damage, wear, or loose connections, as these are common causes of system malfunctions․ Additionally, verify that all devices are properly grounded to prevent electrical hazards․ If issues persist, consult the PAC SNI 35 manual or seek professional assistance to address complex problems․

Regularly testing and inspecting the wiring system can prevent recurring issues․ Documenting findings and implementing corrective actions ensures long-term reliability and safety in PAC SNI 35 installations․

Maintenance and Upkeep

Regular maintenance is crucial for ensuring the longevity and reliability of PAC SNI 35 systems․ Schedule periodic inspections to check for wear, corrosion, or loose connections․ Clean components and replace damaged parts promptly to prevent system failures and ensure optimal performance․

7․1․ Regular Maintenance Practices

Regular maintenance is essential to ensure the PAC SNI 35 system operates efficiently and safely․ Start with a visual inspection of all wiring and connections to identify signs of wear, corrosion, or damage․ Clean dust and debris from components using compressed air or soft brushes․ Check terminal connections for tightness and integrity, as loose connections can lead to system malfunctions․ Test circuit continuity and verify that all components are functioning within specified parameters․ Replace any damaged or corroded parts immediately to prevent further issues․ Schedule maintenance at least quarterly, or more frequently in environments with high humidity or extreme temperatures․ Always power down the system before performing maintenance to avoid electrical hazards․ Keeping detailed records of maintenance activities will help track the system’s condition and plan future upkeep effectively․ Adhere to manufacturer guidelines for replacement parts and tools to ensure compliance and reliability․

7․2․ Upgrade and Replacement Guidelines

Upgrading or replacing components in a PAC SNI 35 system requires careful planning to ensure compatibility and optimal performance․ Always start by disconnecting the power supply to avoid electrical hazards․ Before installing new parts, verify their compatibility with the existing system by consulting the manufacturer’s specifications․ Use only certified tools and materials to maintain compliance with industry standards․ When replacing wiring or components, follow the same routing and connection methods as the original setup to prevent signal interference or damage․ Test all upgraded or replaced components thoroughly before restoring power to ensure proper functionality․ Keep detailed records of all upgrades and replacements for future reference․ Regularly inspect older components for degradation and plan their replacement proactively to avoid sudden system failures․ If unsure about any step, consult a qualified technician to ensure the system remains reliable and safe․ Proper upgrades and replacements will extend the lifespan of your PAC SNI 35 system and maintain its efficiency․