The Fooing Ice Maker is a cutting-edge appliance designed for efficient ice production. With advanced cooling technology and a user-friendly interface, it offers fast, reliable performance, making it ideal for home or commercial use. Its sleek, compact design fits seamlessly into any kitchen, providing fresh, crunchy ice whenever needed. Packed with innovative features, the Fooing Ice Maker ensures convenience and durability, making it a top choice for ice-making solutions.

1.1 Overview of the Fooing Ice Maker

The Fooing Ice Maker is a modern, compact appliance designed for efficient ice production. Equipped with advanced cooling technology and a powerful compressor, it ensures fast and reliable performance. Its self-cleaning feature and user-friendly interface make maintenance easy. Capable of producing crunchy, chewable ice, it suits both home and commercial needs. With a sleek design, it fits seamlessly into any kitchen, offering a convenient solution for fresh ice anytime. Its durability and innovative features make it a top choice for ice-making solutions.

1.2 Key Features of the Fooing Ice Maker

The Fooing Ice Maker boasts advanced cooling technology for fast ice production and a powerful compressor for efficient operation. It features a self-cleaning function, automatic shut-off, and adjustable ice size settings. The compact design allows easy placement in kitchens or bars, while the intuitive control panel ensures seamless operation. With energy-saving modes and smart connectivity options, it offers convenience and durability. The machine also includes a timer function and a large ice storage capacity, making it ideal for both home and commercial use.

1.3 Importance of Reading the Manual

Reading the Fooing Ice Maker manual is essential for understanding its operation, maintenance, and troubleshooting. It provides critical safety precautions, installation guidelines, and usage tips to ensure optimal performance. The manual also explains how to address common issues, such as the red water light or ice production problems, and outlines maintenance procedures like descaling and filter replacement. By following the manual, users can extend the appliance’s lifespan, avoid potential damage, and make informed decisions for efficient ice-making. Proper usage ensures safety, efficiency, and durability.

Unpacking and Installation

Unpack the Fooing Ice Maker carefully, ensuring all components are undamaged. Place it on a level surface, connect to a water supply, and ensure proper drainage for smooth operation.

2.1 Unpacking the Ice Maker

Carefully unpack the Fooing Ice Maker from its box, ensuring all components, including the machine, water tank, and power cord, are undamaged. Inspect for any visible damage or dents. Handle the ice maker gently to avoid scratching or misaligning internal parts. Place it on a stable, flat surface away from direct sunlight. Check the water indicator to ensure it functions properly before proceeding with installation. Refer to the manual for specific unpacking instructions to avoid potential issues during setup.

2.2 Choosing the Right Location

Place the Fooing Ice Maker in a well-ventilated area to ensure proper cooling and efficiency. Avoid direct sunlight, as it may affect performance. Position it near a water supply for easy connection. Keep it away from direct heat sources or appliances that generate excessive vibrations. Ensure the surface is stable and level to prevent uneven operation. Allow sufficient space around the unit for airflow. Proper placement enhances durability and ensures optimal ice production.

2;3 Leveling the Ice Maker

Proper leveling is essential for the Fooing Ice Maker to function correctly. Use a spirit level to ensure the unit is balanced on all sides. Adjust the feet as needed to achieve even balance. An uneven surface may cause vibration or poor performance. Place the ice maker on a stable, hard surface to support its weight and ensure smooth operation. Proper leveling prevents noise, ensures efficient ice production, and extends the lifespan of the machine.

2.4 Connecting to Water Supply

To connect the Fooing Ice Maker to a water supply, ensure the water source is compatible with the machine’s inlet requirements. Attach the provided water hose to the ice maker’s water inlet valve, securing it tightly to prevent leaks. If using a water filter, install it according to the manufacturer’s instructions to improve water quality and prevent scaling. Turn on the water supply slowly and check for any leaks. A stable water connection is crucial for consistent ice production and machine performance.

2.5 Initial Setup and Power-On

After installation, plug in the Fooing Ice Maker and ensure all connections are secure. Turn on the power switch, and the control panel will illuminate, indicating the machine is ready. Allow the unit to cool down for a few minutes before starting ice production. Use the control panel to select your preferred settings. Ensure the water reservoir is filled if applicable. Follow the manual’s guidelines for the first use to ensure proper function and avoid any operational issues. Always refer to the manual for specific startup instructions.

Understanding the Control Panel

The control panel is your gateway to monitoring and adjusting the Fooing Ice Maker’s settings. It features touch-sensitive buttons, status indicators, and a clear display for easy navigation. Use it to set ice size, start/stop production, and monitor water levels. The panel also alerts you to maintenance needs, ensuring optimal performance. Familiarize yourself with its functions to maximize efficiency and ease of use.

3.1 Buttons and Indicators

The Fooing Ice Maker’s control panel features an array of intuitive buttons and indicators. The power button turns the machine on/off, while the ice size button adjusts cube thickness. Indicators include a water level light, signaling when the reservoir is low, and an ice basket full indicator. A red light may appear if there’s a malfunction or maintenance is needed. These features ensure smooth operation and help troubleshoot issues efficiently. Understanding each button and indicator is key to optimal performance.

3.2 Setting the Ice Size

The Fooing Ice Maker allows you to customize ice size using the dedicated ice size button on the control panel. Simply press the button to cycle through small, medium, or large ice cube options. The machine will automatically adjust its settings to produce the selected size. The display will confirm your choice, and production will begin shortly. This feature ensures you can tailor ice size to your specific needs, whether for drinks, cooling, or other applications, enhancing convenience and flexibility.

3.3 Starting and Stopping Ice Production

To start ice production, press the ‘Ice Start/Stop’ button on the control panel. The machine will begin cycling water and freezing it into ice cubes. A blue indicator light will illuminate to confirm operation. To stop production, press the same button; the light will turn off, and the machine will halt. Ensure the ice bin is in place before starting. If the bin is full, the machine will automatically stop and display a ‘Full’ indicator, ensuring efficient and hassle-free operation.

3.4 Understanding the Display Messages

The Fooing Ice Maker features a digital display that shows status updates and alerts. Common messages include ‘Add Water’ when the tank is low, ‘Ice Full’ when the bin is complete, and ‘Cleaning Mode’ during maintenance. Error codes like ‘E1’ or ‘E2’ indicate issues such as sensor malfunctions or overheating. Refer to the manual for specific code meanings. The display also shows ice size settings and operational modes, ensuring clear communication for smooth operation and troubleshooting. Always monitor the display for optimal performance.

Maintenance and Cleaning

Regular maintenance ensures optimal performance and longevity of the Fooing Ice Maker. Clean the machine daily, descale every 3-6 months, and replace the water filter quarterly. Sanitize regularly to prevent mold and bacteria growth, and perform deep cleaning cycles as recommended. Proper upkeep prevents mineral buildup and maintains ice quality, ensuring your appliance runs efficiently for years to come.

4.1 Daily Cleaning Tips

For daily maintenance, wipe down the Fooing Ice Maker’s exterior with a damp cloth to remove dust and splatters. Clean the ice bucket and chute regularly with mild soap and warm water to prevent mold. Check the water reservoir and drain any unused water to avoid bacterial growth. Dry all surfaces thoroughly after cleaning to prevent mineral spots. Regular daily cleaning ensures optimal hygiene and ice quality, maintaining your appliance’s efficiency and longevity effectively.

4.2 Deep Cleaning the Ice Maker

Perform a deep clean every 1-2 months to maintain your Fooing Ice Maker’s performance. Mix a solution of water and white vinegar or a descaling agent. Pour the solution into the water reservoir and run a full ice-making cycle to circulate it through the system. Repeat until the water runs clear. Scrub the interior with a soft brush to remove any buildup. Rinse thoroughly by running clean water through the machine. This process ensures the removal of mineral deposits and bacteria, keeping your ice fresh and the machine functioning smoothly.

4.3 Descaling the Machine

Descaling your Fooing Ice Maker is essential to remove mineral buildup and prevent damage. Use a descaling solution or white vinegar mixed with water. Pour the solution into the water reservoir and run a full ice-making cycle. Allow the machine to complete the process, then rinse thoroughly by running clean water through it. Repeat if necessary. Regular descaling ensures optimal performance, prevents clogs, and maintains the quality of your ice. Always follow the manufacturer’s recommendations for descaling frequency and methods.

4.4 Replacing the Water Filter

To ensure clean ice production, replace the water filter every 6 months or as indicated by the machine. Turn off the power and locate the filter, usually near the water inlet. Remove the old filter by turning it counterclockwise, then install the new one by turning it clockwise until it clicks. Flush the system by running a few cycles with clean water to remove any impurities. Replace the filter only with a genuine Fooing Water Filter for optimal performance and water quality. Regular replacement prevents bad taste and odor in the ice.

4.5 Sanitizing the Ice Maker

Sanitizing the Fooing Ice Maker is essential to maintain hygiene and prevent bacterial growth. Mix a solution of 1 part white vinegar to 2 parts water. Pour the solution into the water reservoir and run a complete ice-making cycle. Repeat this process twice to ensure thorough cleaning. After sanitizing, rinse the reservoir with clean water and run additional cycles to flush out any vinegar taste. Regular sanitization ensures clean, fresh-tasting ice and prevents contamination. Always unplug the machine before starting the sanitizing process for safety.

Troubleshooting Common Issues

Identify symptoms like the red water light or no ice production. Check water levels, ensure proper installation, and consult the manual for solutions to common problems.

5.1 Ice Maker Not Turning On

If the Fooing Ice Maker fails to turn on, ensure it’s properly plugged in and the outlet is functioning. Check the power button for damage and verify that the child lock feature isn’t activated. If issues persist, consult the manual or contact customer support for further assistance to resolve the problem effectively and safely.

5.2 Red Water Light is On

The red water light indicates low water levels or a potential issue with the water supply. Ensure the water tank is filled to the recommended level. If the light remains on, check for blockages in the water inlet or kinks in the supply hose. Clean or replace the water filter if necessary. If the issue persists, refer to the troubleshooting guide or contact customer support for further assistance to resolve the problem effectively.

5.3 Ice Maker Not Producing Ice

If the Fooing Ice Maker stops producing ice, check if the water tank is empty or improperly aligned. Ensure the ice basket is not full, as this can halt production. Verify that the power switch is on and all buttons are functioning correctly. If the issue persists, inspect the water supply line for kinks or blockages. Also, ensure the machine is set to the correct mode. If none of these steps resolve the issue, consult the troubleshooting guide or contact customer support for professional assistance.

5.4 Excessive Noise or Vibration

If your Fooing Ice Maker produces excessive noise or vibration, ensure it is properly leveled and placed on a stable surface. Check for loose components or debris inside the machine. Vibrations may occur during the ice-making cycle due to imbalanced water flow or ice buildup. If the issue persists, turn off the machine, unplug it, and clean the interior. Contact customer support if the problem remains unresolved after these steps.

5.5 Ice Sticking Together

If ice sticks together, it may be due to high humidity, improper water quality, or incorrect ice size settings. Regularly cleaning the ice maker and ensuring proper drainage can help prevent this issue. Check the ice basket for blockages and ensure it is not overfilled. If ice continues to clump, consider adjusting the ice thickness setting or using filtered water. Descale the machine periodically to maintain optimal performance and reduce the likelihood of ice sticking together.

Advanced Features and Settings

The Fooing Ice Maker offers advanced features like a timer function, auto-shutoff, and energy-saving mode. It also includes smart connectivity options for seamless control via your smartphone, ensuring convenience and efficiency. These settings make it perfect for tech-savvy users seeking customizable and energy-efficient ice production solutions. The machine’s advanced cooling technology ensures fast and reliable performance, making it ideal for both home and commercial use.

6.1 Timer Function

The timer function on the Fooing Ice Maker allows users to schedule ice production in advance. This feature is perfect for preparing ice ahead of time for events or daily use. Simply set the desired time, and the machine will start making ice automatically. The timer ensures that you always have fresh ice when needed, without constant monitoring. It’s a convenient and energy-efficient way to manage ice production, aligning with your schedule seamlessly. This feature enhances user experience by offering flexibility and control over ice-making processes.

6.2 Auto-Shutoff Feature

The Fooing Ice Maker’s auto-shutoff feature automatically turns off the machine when the ice basket is full or when a malfunction is detected. This prevents overproduction and energy waste. It also ensures safety by halting operations if issues like low water levels or excessive vibration occur. The feature promotes efficient energy use and extends the machine’s lifespan by avoiding unnecessary operation. It’s a convenient and eco-friendly option that enhances user safety and appliance durability. This function is particularly useful for busy households or commercial settings where constant monitoring isn’t feasible.

6.3 Energy-Saving Mode

The Fooing Ice Maker’s energy-saving mode optimizes power consumption without compromising performance. This feature reduces electricity usage by adjusting cooling cycles and compressor speed during non-peak times. It ensures efficient operation while maintaining ice production quality. Activating this mode is ideal for eco-conscious users, as it lowers energy bills and environmental impact. The energy-saving mode is seamlessly integrated, providing a balance between performance and sustainability. It’s a practical choice for both residential and commercial settings aiming to reduce energy costs while maintaining productivity.

6.4 Smart Connectivity Options

The Fooing Ice Maker offers advanced smart connectivity features, enabling seamless integration with smart home systems. Users can control the ice maker via voice commands or through a dedicated app, allowing remote monitoring and adjustments. This feature enhances convenience by enabling scheduling, real-time notifications, and customization of settings. Smart connectivity also provides energy usage insights, helping users optimize their consumption. Compatible with leading smart platforms, this feature ensures a modern, interconnected experience, making it easier to manage ice production efficiently and intelligently from anywhere.

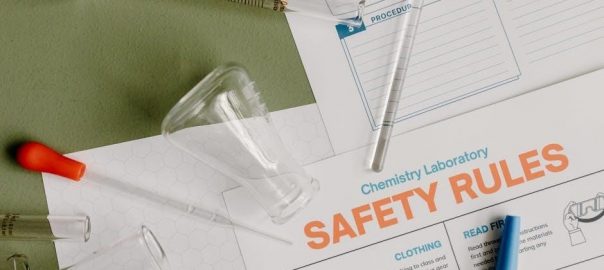

Safety Precautions

Ensure electrical safety by keeping the appliance away from water and using grounded outlets. Avoid overloading the ice maker and keep children away for safe operation.

7.1 Electrical Safety Tips

To ensure safe operation, always use the Fooing Ice Maker with a properly grounded electrical outlet. Avoid exposing the appliance to water or moisture, as this can lead to electrical hazards. Never submerge the unit in water or operate it near flammable materials. Regularly inspect the power cord for damage and replace it immediately if worn. Keep the ice maker on a stable, level surface to prevent accidental tipping or electrical issues. Always follow the manufacturer’s guidelines for electrical connections and avoid overloading circuits to maintain a safe environment.

7.2 Avoiding Overloading

Avoid overloading the Fooing Ice Maker to ensure optimal performance and safety. Do not exceed the recommended ice production capacity or water level, as this can strain the machine. Regularly clean and maintain the unit to prevent blockages that might lead to overloading. Ensure the water supply is stable and not excessive, as this can cause electrical or mechanical issues. Always follow the manufacturer’s guidelines for capacity and usage to prolong the appliance’s lifespan and prevent potential hazards.

7.3 Child Safety Measures

To ensure child safety, keep children away from the Fooing Ice Maker. Install child safety locks if available. Supervise kids near the appliance to prevent accidental start-ups or injuries. Avoid letting children play with buttons or removable parts, as this could damage the machine or cause harm. Regularly inspect for loose components and secure them. Teach children not to insert objects into openings or pull cords. Store ice in a safe location to prevent slipping or accidents. Always prioritize caution to protect both the appliance and your family.

7.4 Handling Ice Safely

Always handle ice with care to avoid injuries. Use a towel or gloves to prevent direct contact with cold surfaces. Keep the area around the ice maker dry to reduce slipping hazards. Lift ice buckets or trays securely to avoid spills. Store ice in a designated container away from children. Never use bare hands to scoop ice, as this can cause frostbite. Ensure proper ventilation when handling ice to prevent moisture buildup. Regularly clean up melted water to maintain a safe environment.

Warranty and Support

Your Fooing Ice Maker is backed by a comprehensive warranty covering parts and labor for a specified period. For support, contact our dedicated team or visit authorized service centers for professional assistance. Register your product to ensure warranty validity and access exclusive updates. Our customer care is committed to resolving issues promptly, ensuring your ice maker performs optimally. Refer to the warranty document for detailed terms and conditions.

8.1 Understanding the Warranty

The Fooing Ice Maker warranty covers manufacturing defects in materials and workmanship for a specified period. It typically includes repair or replacement of defective parts at no cost. Coverage duration varies by model, with most warranties lasting one to two years. Proper installation and maintenance are required to maintain warranty validity. Exclusions include damage from misuse or unauthorized repairs. Review the warranty document provided with your purchase for full details and conditions.

8.2 Contacting Customer Support

For assistance with your Fooing Ice Maker, contact customer support via phone, email, or live chat on their official website. Support is available during business hours. Visit the website for contact details and additional resources. Have your model number ready for faster service. Phone support is toll-free, and emails are typically responded to within 24-48 hours. Online resources include FAQs and user manuals. For troubleshooting, refer to the support section or contact a representative for personalized help.

8.3 Finding Authorized Service Centers

To locate an authorized service center for your Fooing Ice Maker, visit the official website and use the service center search tool. Enter your location or ZIP code to find nearby authorized centers. You can also contact customer support for assistance in finding a certified service provider. Ensure to only use authorized centers for repairs to maintain warranty validity and ensure reliable service. The support team is available to guide you through the process and answer any questions regarding service locations.

Environmental Considerations

Proper disposal, recycling, and energy efficiency are key. The Fooing Ice Maker promotes eco-friendly practices, ensuring minimal environmental impact while maintaining performance and sustainability for a greener future.

9.1 Proper Disposal of Waste

When disposing of your Fooing Ice Maker, ensure all electrical components are handled responsibly. Recycle metal and plastic parts through authorized facilities to minimize environmental impact. Remove any hazardous materials like refrigerants and batteries, following local regulations. Proper disposal helps conserve natural resources and reduces landfill waste, aligning with eco-friendly practices. Always check local guidelines for specific instructions on appliance disposal to ensure compliance and environmental safety.

9.2 Recycling Options

Recycling your Fooing Ice Maker is environmentally responsible. Separate plastic, metal, and electronic components for proper recycling. Check local facilities that accept appliance materials. Many centers specialize in recycling refrigeration units, ensuring harmful substances are safely handled. Participating in recycling programs helps reduce waste and conserves resources. Contact your municipal waste management for guidance on recycling large appliances. Proper recycling supports sustainability and reduces environmental impact. Always follow local regulations for eco-friendly disposal.

9.3 Energy Efficiency Tips

Maximize energy efficiency by using the Fooing Ice Maker’s energy-saving mode, which reduces power consumption during off-peak hours; Ensure proper ventilation around the unit to prevent overheating, as this can increase energy use. Regularly clean the condenser coils to maintain optimal performance. Always unplug the machine when not in use to avoid standby power consumption. Use the timer function to produce ice only when needed, reducing unnecessary cycles. Proper maintenance, like descaling, also improves efficiency. These practices help lower energy bills and extend the machine’s lifespan.

Frequently Asked Questions (FAQs)

- Can I use the ice maker outdoors? No, it’s designed for indoor use only.

- How long does it take to make ice? Typically 6-8 minutes for a batch.

- Can I adjust the ice thickness? Yes, via the control panel settings.

- What if the machine leaks water? Check connections and ensure the drain is clear.

10.1 Can I Use the Ice Maker Outdoors?

The Fooing Ice Maker is designed for indoor use only. Using it outdoors may expose it to extreme temperatures, humidity, and weather conditions, which can damage the machine. Additionally, outdoor use may void the warranty and pose safety risks due to electrical components. For optimal performance and safety, keep the ice maker in a climate-controlled indoor environment. Ensure it is placed on a stable, flat surface away from direct sunlight and moisture. Always follow the manufacturer’s guidelines for usage.

10.2 How Long Does It Take to Make Ice?

The Fooing Ice Maker typically produces ice in about 6-12 minutes per batch, depending on the selected ice size. Smaller ice cubes take less time, while thicker ones may require up to 15 minutes. The machine’s advanced cooling system ensures rapid freezing, making it efficient for both small and large ice production needs. Keep the water reservoir filled and the machine clean for optimal performance. Monitor the ice basket capacity, as it can hold up to 1.5 lbs of ice, allowing for continuous production throughout the day.

10.3 Can I Adjust the Ice Thickness?

The Fooing Ice Maker allows you to adjust ice thickness to suit your preferences. Using the control panel, you can select from preset ice size options, typically ranging from small to large. This feature ensures you can customize the ice for drinks, cooling, or other uses. Adjusting the thickness may slightly affect production time, but the machine maintains efficiency. Always refer to the manual for specific instructions on selecting ice sizes and optimizing performance for your needs.

10.4 What if the Ice Maker Leaks Water?

If your Fooing Ice Maker leaks water, turn it off immediately and unplug it. Check the water supply connections for tightness and inspect the drain for blockages. Ensure the water filter is properly installed and not damaged. If the issue persists, consult the manual for troubleshooting steps or contact customer support for assistance. Regular maintenance, such as descaling and filter replacement, can help prevent leaks and maintain optimal performance.